- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

China

LC, T/T

CE, ISO, UL, QS, GMP

1 Year

1-3 months

| Availability: | |

|---|---|

Product Description

Engineering plastics pellets are granular forms of specialized plastics designed to meet specific mechanical, thermal, or chemical requirements. These materials are formulated to withstand high temperatures, resist corrosion, and maintain structural integrity under stress, making them suitable for demanding applications like automotive parts and medical devices.

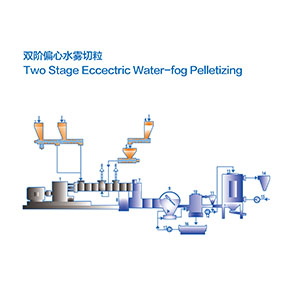

JWELL Machinery, a leading manufacturer, produces advanced compounding extrusion machines designed to process these pellets with precision and efficiency. JWELL's twin-screw compounding extrusion machines are available with screw diameters from 25mm to 95mm, supporting production capacities from 20 kg/h to 3,000 kg/h. This range accommodates both specialized and high-volume manufacturing needs. They can process a wide range of materials, from high-viscosity polymers to low-density fillers, ensuring consistent and high-quality output compared to single-screw extruders.

| Model | L/D | Speed | Capacity |

|---|---|---|---|

| CJWH65 | 36–48 | 400–900rpm | 300–800kg/h |

| CJWH75 | 36–48 | 400–900rpm | 500–1000kg/h |

| CJWH95 | 36–48 | 400–900rpm | 800–1500kg/h |

Engineering plastics pellets are used to produce automotive parts like dashboards, bumpers, and engine covers. These components reduce vehicle weight, improving fuel efficiency while maintaining durability.

Automotive applications require materials with high impact resistance and thermal stability to ensure reliable performance under demanding conditions.

Engineering plastics pellets are used to create electronic components like connectors and casings, requiring precise tolerances and consistent quality for reliability.

Pellets formulated with flame-retardant properties are essential for electronics to meet safety regulations and protect devices from fire hazards.

In healthcare, engineering plastics pellets are used for biocompatible devices like syringes and implants, meeting strict medical standards for safety and performance.

For packaging, these pellets produce durable films and containers for food and medical applications, ensuring high quality and reliability.

Engineering plastics pellets include biodegradable options like PLA and PBAT, supporting the production of environmentally friendly products.

Pellets can be made from recompounded scrap plastic, promoting recycling efforts and reducing waste in manufacturing processes.

JWELL Twin Screw Compounding Extrusion Machine.pdf

JWELL Twin Screw Compounding Extrusion Machine.pdf

FAQ

Who We Are?

Jwell Machinery is a leading Chinese manufacturer specializing in the production of extrusion machinery, particularly for the plastic processing industry. Founded in 1997, Jwell has become one of the largest and most well-known manufacturers of plastic extrusion equipment in China and is recognized globally for its high-quality products.

Quick Links