- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

China

LC, T/T

CE, ISO, UL, QS, GMP

1 Year

1-3 months

| Availability: | |

|---|---|

Product Description

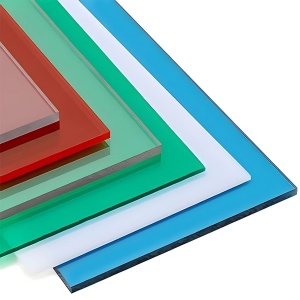

PC, PMMA and GPPS sheets offer unmatched strength, transparency and versatility for applications ranging from construction to electronics. JWELL's PC PMMA GPPS sheet extruders boost production capabilities with advanced features such as optimized screws, precise T-die heads and global support. Whether manufacturing roof panels or display panels, JWELL delivers quality, efficiency and economy. Are you ready to take your production to the next level? JWELL's machines are your answer.

型号 Model | JWS130/38-2400 | JWS120/38-1500 | JWS120-1300 |

适用原料 Material | PC, PMMA, GPPS, ABS | PC, PMMA, GPPS, ABS | PC |

制品宽度 Products Width | 2100mm | 1220mm | 1000mm |

制品厚度 Products Thickness (mm) | 1.0-10mm | 1.0-10mm | 0.125-1.2mm光学片 |

挤出机规格 Extruder Specification | Ø130/38; Ø45/30 | Ø120/38 | Ø120/38 |

最大挤出产量 Capacity (Max.) | 550kg/h | 450kg/h | 400kg/h |

Imagine a building with a roof that lets in sunlight but withstands storms. PC sheets are the material of choice for roofs and skylights in homes, offices and commercial spaces due to their strength and high light transmittance. PMMA and GPPS are used for budget-friendly or decorative roof projects, providing clarity and ease of installation.

Modern buildings often feature transparent, stylish exterior designs, and PC, PMMA and GPPS sheets are ideal for achieving this effect. PC provides durability, while PMMA and GPPS add beauty with their clear, smooth surfaces to enhance the appearance of the building.

Have you ever noticed those brightly colored billboards that catch the eye? PMMA and GPPS sheets are widely used in signage, providing clarity for posters, ultra-thin light boxes and advertising displays. PC sheets are used for outdoor signage that needs to withstand the elements.

In industrial settings, PC sheets are used as machine shields or noise barriers, providing visibility and strength. PMMA is used for transparent shields, while GPPS is used for cost-effective panels with less impact resistance requirements.

Why do high-end luggage look durable and stylish? PC and ABS/PC composite sheets are used in luggage to provide impact resistance and a smooth surface. PMMA adds a scratch-resistant layer to high-end luggage for increased durability.

ABS/PMMA composite sheets are popular in bathroom products, from bathtubs to shower enclosures. They combine the smooth surface of PMMA with the toughness of ABS to create a durable, easy-to-clean, and corrosion-resistant surface.

Have you ever marveled at the crisp picture on your TV or monitor? PMMA and GPPS sheets are used in LCD and LED panels to provide clear vision. PC sheets are used in protective layers for electronics to ensure durability.

PMMA's high transparency makes it ideal for lenses and light guides in sunglasses, helmets, and medical devices. PC's strength is used in mobile phone protective films to provide scratch and impact resistance.

The renewable energy sector uses PC and PMMA sheets to make solar panel covers, leveraging their durability and light transmission. GPPS sheets are used in less demanding parts, providing a cost-effective solution.

PC and PMMA sheets are used in automotive applications, from lightweight windshields to dashboard panels, to improve safety and aesthetics. GPPS is used in cost-sensitive interior parts.

FAQ

Who We Are?

Jwell Machinery is a leading Chinese manufacturer specializing in the production of extrusion machinery, particularly for the plastic processing industry. Founded in 1997, Jwell has become one of the largest and most well-known manufacturers of plastic extrusion equipment in China and is recognized globally for its high-quality products.

Quick Links