- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-31 Origin: Site

Influenced by market drivers, the construction industry on the gradual improvement of waterproof life requirements, the promotion of new policies, urbanisation and the demand for renovation of old districts, the market for waterproofing membranes put forward a higher standard of requirements.

The quality of waterproofing project, starting from the material, into the process!

For example, in the field of building waterproofing, the performance bottlenecks and process limitations of traditional materials often become the source of hidden engineering problems.

How to break through the technical barriers to produce higher strength, more resistant to aging, more environmentally friendly waterproofing membrane?

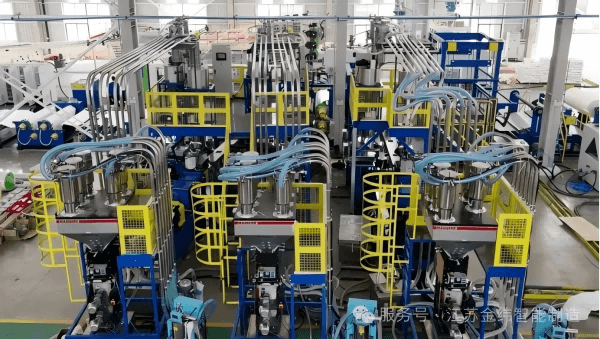

In the field of construction waterproofing, the performance of the material and production process directly determines the quality and durability of the project. Jwell machinery with years of technical accumulation and innovation, the introduction of composite polymer waterproofing membrane production line, with high efficiency, stability, intelligent production solutions to help the waterproofing industry towards a higher standard.

The composite stiffened polymer waterproof coil equipment suitable for PE, EVA, TPO, PVC and other polymer material coil production.

Through high-precision sensors and intelligent control technology, it realises accurate measurement, automatic proportioning and efficient conveying of various materials, ensuring that the components are quickly mixed according to the preset proportion.

The composite stiffened polymer waterproof coil equipment can be used in the same direction parallel twin screw extruder, efficient single screw extruder, conical twin screw extruder models.

It can be equipped with a full set of automatic robot unpacking, computer automatic proportioning and feeding, automatic mold, automatic thickness measurement, automatic winding, weighing and other automatic equipment.

Jwell Machinery redefines the quality standard of waterproof material with intelligent manufacturing, precision control and efficient production!

Composite polymer waterproofing roll-roofing production line can efficiently produce roll-roofing with high strength, ageing resistance and excellent waterproofing performance.

Widely used in building roofing, underground engineering, bridges and tunnels and other waterproofing areas, for all kinds of projects to provide durable and reliable waterproofing protection.

Particularly suitable for:

✔ The preferred waterproof material for roofing of large industrial plants, public buildings and so on.

✔ Drinking water reservoirs, bathrooms, basements, tunnels, grain stores, subways, reservoirs and other waterproof and moisture-proof projects.

Jwell Machinery independently develops and processes screws, barrels, moulds, rollers, screen changers, etc., and strictly controls the quality of key components.

Comparable to the quality of top German extruders at a reasonable and affordable price. High efficiency single screw extruder and twin screw extruder.

With offices in Vietnam, Turkey, Thailand, Brazil, and Canada, Jwell has more than 800 engineers specialising in their fields to serve customers worldwide.

Jwell provides regular spare parts delivery service within 24 hours, professional maintenance advice and lifelong equipment maintenance service.

Empower, Expand, Build | JWELL Machinery 2026 Marketing Conference

Manufacturer vs Trading Company: What’s the Real Difference in Plastic Extrusion Machines?

Plastic Extrusion Machine Solutions by Application: Pipes, Profiles, Sheets and Films

How To Choose A Reliable Plastic Extrusion Machine Manufacturer: A Complete Buyer’s Guide

JWELL Machinery K2025 Dusseldorf: A Showcase of Chinese Manufacturing on The World Stage

Inside a Plastic Extrusion Machine Factory: How JWELL Ensures Quality, Precision and Reliability

Quick Links